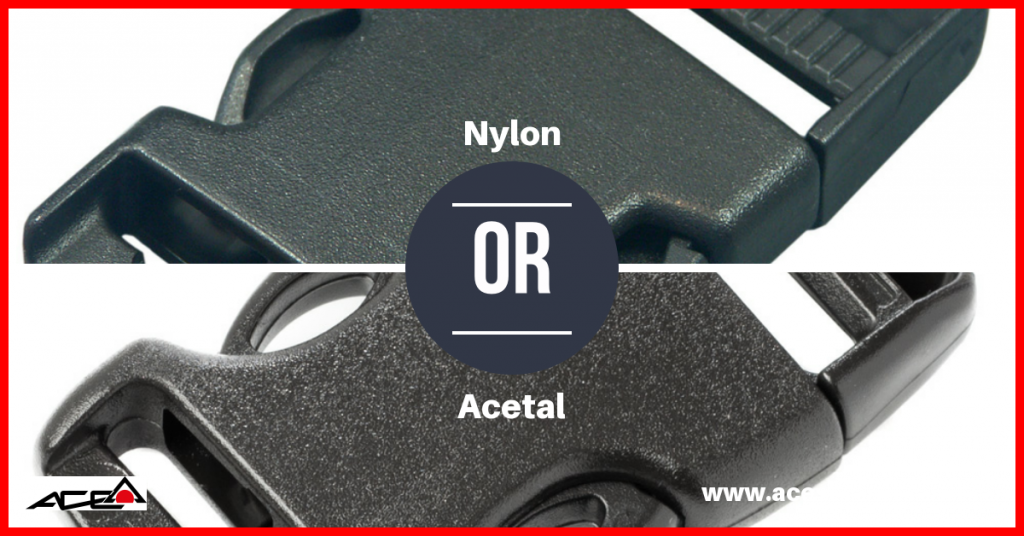

Here at Ace Supplies HQ, we get asked this question a lot! If we compare Acetal and Nylon we can see the differences in strength and advised conditions.

Acetal is a thermoplastic polymer material. In looks it is shinier than Nylon. It is well known for its excellent tensile strength and chemical resistance. Acetal is also recognised for its flexural memory when put under pressure over a long period of time. This handy little plastic buckle is great at withstanding extreme conditions too. From -40 °C to 60 °C. Acetal is recommended for high performance use due to how versatile it is however it can be more expensive. acetal is slightly lighter than nylon but there is not a large difference between the two.

Super tough nylon and regular nylon are a thermoplastic poly amide resin. Appearance wise, this material is duller. What makes this type of buckle stand out is its ability to withstand repeated impact loads. Nylon is excellent in high-temperature applications. The ideal short-term temperature range is 40°C to +199°C. There is also a flame retardant nylon available that is specially suited to situations where they will come into contact with fire. Due to the materials used to create nylon, it isn’t the best under repeated humidity changes. When dry, tensile strength is higher and impact is lower. When wet, tensile strength is low, and impact defence is very high. Be aware however that when wet, nylon can swell.

In summary, it depends on your product! The use will determine the right material. Some will be better with the advantages of Acetal, whilst other will be better with the capabilities of Nylon. If you’re still not sure what is going to be best for your products, you can contact our friendly and quick team today!